Made in America

We Got Creative, Our Customer Avoided Offshoring

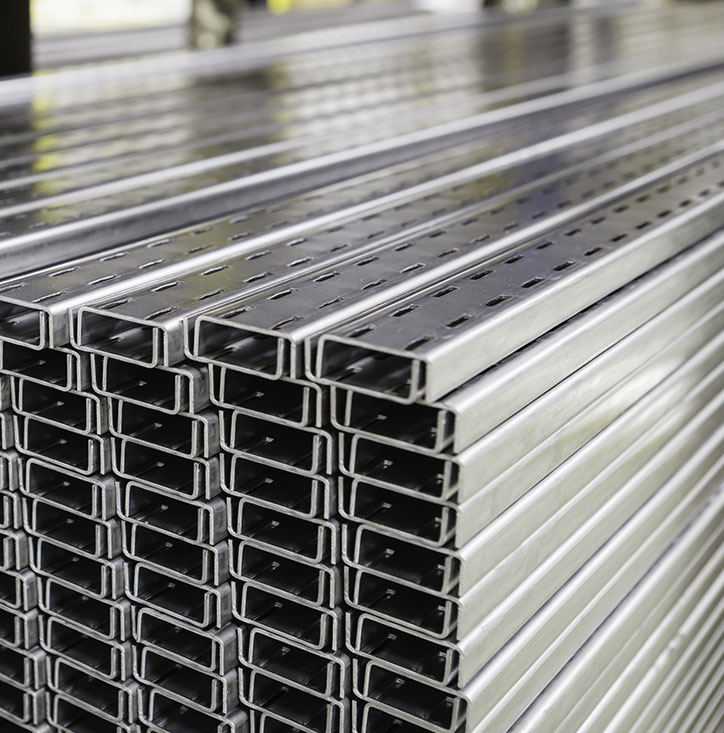

One of our customers who designs and manufactures retail fixture displays was looking for ways to reduce costs and, like so many other companies, considered moving production overseas. As their current supplier and as a proponent of US manufacturing, this was bad news for us.

The overseas supplier had offered to produce the store fixture completely assembled, with plastic components screwed to the metal components, at a price only slightly higher than what we were charging for just the metal components. Given the high cost of labor in the United States, there was no way we could manufacture and assemble the parts while meeting the desired price. But then we had an idea.

We asked the customer to give us 6 weeks to come up with a solution for reducing cost and avoid the nightmare of offshoring. Our customer and their client who was calling the shots granted us our requested development time.

Thinking outside the box, the Steel Forming design team envisioned a machine that would save cost for all parties. The machine was designed to automate the assembly of the plastic and metal components without using much manual labor. We were able to design, build and test the machine, and begin assembling units before our 6 week deadline.

We reduced the required labor from six individuals to one and beat the overseas price by five cents per unit. That might not seem like a lot, but it saved our customer several thousands of dollars per year and kept the manufacturing in the United States.

Talk To Us – We’re Here To Help

Provide information about your Roll Forming project, and let’s get the conversation started.